![]()

Quick Refinishing for the automotive sector

A must-have for any car bodyshop. Take a look at the renowned paintTROTTER Refinish by Lagos

Basics of the paintTROTTER

PLACING AND CONNECTING

Plug and play product. The operator places the paintTROTTER close to the vehicle at any point in the working area. Then the worker must simply plug it into the relevant body shop connections.

CLOSING THE BOOTH

The next step consists on attaching the protection film and applying the masking tape by cutting the film to shape so the technician can work on the area to be painted. With this easy operation the paintTrotter is completely sealed and ready to start the repair process.

SANDING, PAINTING, POLISHING

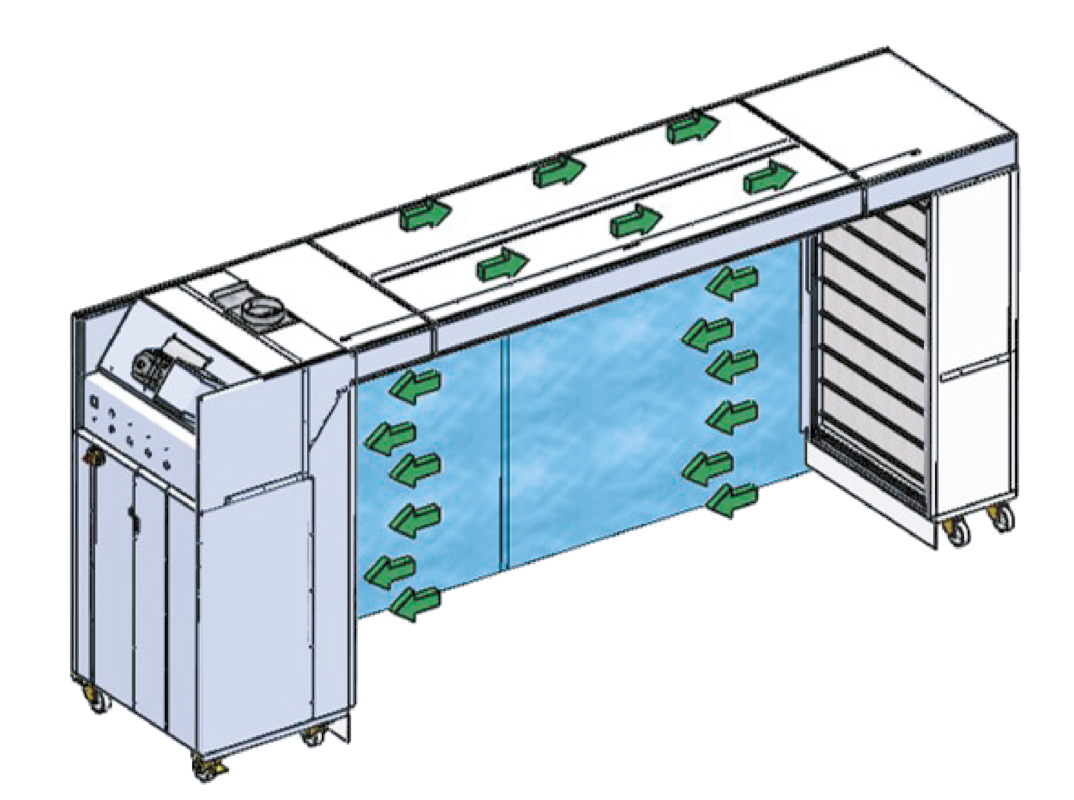

paintTROTTER becomes a closed booth system, where you can work in a space that is clean of dust and dirt thanks to its efficient air recycling system. At the same time, paint overspray and dust do not get into other areas of the body shop, they are retained within the enclosed area of the paintTrotter.

DRYING

The paintTrotter can also incorporate optional short-wave infrared equipment to reduce drying times. This system reduces process times by a third in comparison to the time needed in a traditional spray booth.

Why to consider paintTROTTER as a new equipment for your company

paintTROTTER helps us to maximize preparation, painting and drying times for small repairs. The easy use and mobility of the paintTROTTER in the body shop environment helps to optimize repair times and ultimately see productivity and profits increase

With paintTROTTER we have created a flexible working area for more repairs to be done at the same time. No more vehicle movements in order to perform work in a specific area.

Get more profitability in your small area repairs. Low maintenance and low operation costs make paintTROTTER the best solution to include in the body shop small repair process.

High energy costs are reduced, and thanks to its low energy consumption paintTROTTER is the best piece of equipment to reduce small damage repair costs.

Some videos of different repairs done with paintTROTTER

Click on the following link to download our product catalogue

Share this pdf with your business associates and partners and introduce them to a lean refinishing future…

Most frequently asked questions from our clients

paintTROTTER is a plug and play product. You just need to connect the power socket to the power supply to start the equipment.

paintTROTTER adapts perfectly to a wide range of vehicles, machines and industrial components, and so our customers use paintTROTTER to repair cars, bus, trolleybus, trams, trains and metro, motorbikes, lorries and industrial components for construction, furniture, renewable energies…

No, absolutely not. No works or special adaptations are necessary, nothing at all. You just need space enough to move paintTROTTER comfortably and approach it to the vehicle/machine/component. After this, you only need to connect paintTROTTER to the electrical power.

Only one worker is necessary to operate paintTROTTER.

paintTROTTER has a 5+1 stages filtration system, which filters the VOCS microparticles (volatile organic compounds) to keep clean the air in the working area where the operator performs the reparation.

No, paintTROTTER can be easily moved and approached to the vehicle/machine. You don’t need to move the vehicle/machine.

Technical features may change without notice. Check out with us for updates.

| Length | 4.300 mm |

| Width | 1.100 mm |

| Height | 2.160 mm |

| Mechanics | Electrical (mono or tri) |

| Extracted airflow | 6.000 m3/h |

| Air speed (measured at filter exit) | 1 m/s |

| Average air speed | 0,5 – 0,8 m/s |

| Average light intensity | 1500 lux |

| Built-in lighting | ATEX |

| Sound levels | 65dB @ 1 meter |

| VOCs retention capacity | 60 – 97% |

| Engine power | 2,2 Kw |

| Lighting power | 0,23 Kw |

| Filtration system |

5 Stages + 1 |

Check out the available models and characteristics

The standard version (STD) of the paintTROTTER Refinish is the most commonly used with normal workloads in countries where legislation allows partial recirculation of filtered air from the paint booth.

The 5+1 stages filtration system allows only a residual part of the VOCs to be expelled outside the booth, thus maintaining the healthiness of the environment at optimal working levels.

The STD version has greater mobility since it only depends on an electrical outlet for its operation and can be easily moved where it is needed.

The EVO version of paintTROTTER is especially useful in environments with high workloads or in Countries where legislation does not allow any type of air recirculation in spray booths.

With two perfectly calibrated impulsion and extraction motors, the paintTrotter manages to expel the air outside the workshop by means of a flexible duct, while harmful VOCs have previously been filtered so the air expelled comest outside clean.

Thanks to this system, the maintenance cost is significantly low by reducing the number of filtration stages.